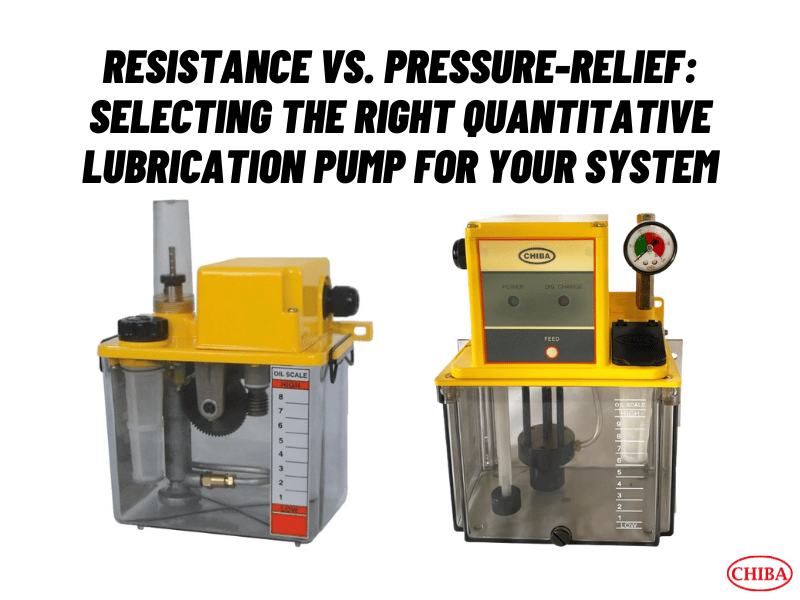

Resistance vs. Pressure-Relief: Selecting the Right Quantitative Lubrication Pump for Your System

In the industrial fluid handling market, selecting a fuel oil dispenser involves more than just choosing a container and a nozzle. The efficiency of your machinery depends heavily on the underlying pump technology and distribution logic. Two primary systems dominate the industry: Resistance Type and Pressure-Relief Type. Understanding the difference between these two is essential when integrating an auto pump into your production line.

1. Resistance Type Systems: Simplicity and Efficiency

A resistance-type lubricator is often the first choice for standard industrial applications. This system operates by using an auto gear pump to create continuous pressure, pushing oil through proportional distributors (metering units) to various lubrication points.

- How it works: Oil is delivered directly to the friction points while the pump is running. The amount of oil is controlled by the diameter of the orifice in the distributor.

- Best for: Conveyor belts, simple textile machinery, and equipment where precise volume control per point is less critical.

- Key Benefit: It is cost-effective, easy to install, and provides a steady flow of lubricant as a part of a general auto pump setup.

2. Pressure-Relief Type: The Precision of Quantitative Lubrication

For high-precision machinery, such as CNC centers and automated processing equipment, a quantitative lubrication pump (Pressure-Relief type) is the gold standard. Unlike resistance systems, this technology ensures that every lubrication point receives an exact, measured amount of fluid, regardless of its distance from the pump.

- How it works: This is a two-stage process. First, the pump builds pressure to "load" the volumetric distributors. The actual lubrication occurs during the "pressure-relief" phase (when the pump stops), and the stored oil is discharged by spring action. This ensures a true quantitative lubrication cycle.

- Best for: High-speed spindles, linear guides, and complex automated production lines.

- Key Benefit: It eliminates oil waste and prevents equipment failure due to under-lubrication, as each point is guaranteed a fixed volume per cycle.

Advanced Integration: From Grease to Oil Mist

Beyond standard oil distribution, modern industrial environments often require specialized solutions. For heavy-duty bearings or gears, an auto grease pump provides the necessary torque and pressure for higher viscosity lubricants.

Conversely, for high-speed cutting or milling where cooling is just as important as lubrication, an oil mist cooling system can be integrated. This system atomizes the fluid to manage thermal expansion while providing a thin protective film. For large-scale operations with numerous friction points, a progressive lubrication system can be implemented to monitor each point sequentially, providing a level of reliability that a basic fuel oil dispenser simply cannot match.

Conclusion: Which One is Right for You?

Choosing between a standard resistance-type lubricator and a precision quantitative lubrication pump depends on your equipment's precision requirements and your long-term maintenance goals. While resistance systems offer simplicity, pressure-relief systems offer unmatched precision and cost savings through reduced oil consumption.

At Chiba, we provide a full spectrum of fluid management technology, from the reliable auto gear pump to advanced progressive lubrication systems. Upgrade your fuel oil dispenser setup today with our precision-engineered components to ensure your machines run smoother for longer.

Explore our full range of solutions at: www.chiba-tw.com